Betolar strengthens Finland's and EU's self-sufficiency in critical and strategic raw materials

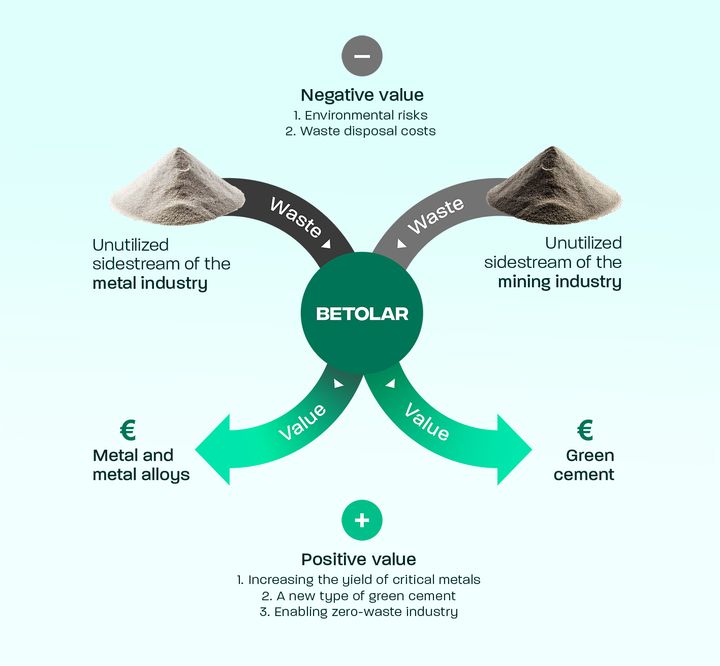

Betolar's newly developed innovative method combines the separation of metals from waste material with the production of green cement. The method enables the recovery of valuable materials, such as critical and strategic metals, with exceptionally high yields from the unused slags of the metal industry and the tailings of the mining industry.

In addition, the key advantage of the method is the further processing of the residual slag, purified from valuable fractions, into a low-carbon binder, green cement developed by Betolar, within the same process. All material fed into the process is utilized as valuable products.

"A breakthrough in metal separation and low-carbon binder production is a significant step forward for us. Our vision and goal from the beginning have been to develop our own low-carbon binder to replace cement for concrete products. Now we have succeeded," says Betolar's President and CEO Tuija Kalpala.

Betolar has filed seven new patent applications to strengthen the protection of the new method in addition to previously filed patents.

"The method developed by Betolar is the result of very long-term research and development work. It offers a concrete solution to both increasing self-sufficiency in critical minerals and the global climate change challenge," says Kalpala.

Significant value from unused sidestreams without burdening the environment

The mining industry generates tens of billions of tons of tailings annually, in addition to what has already been generated in both existing and closed mines. Harmful substances leaching from tailings into the environment constitute one of the world's largest environmental problems, but on the other hand, these tailings contain enormous untapped potential for strategic and critical raw materials. Similarly, the metal industry generates approximately 500 million tons of unused slag containing residual metals annually globally. In addition, large amounts of previously generated slag are stored.

With Betolar's new method, this potential can be utilized while reducing environmental risks. Furthermore, the significant amount of residual material from the metal separation process can be entirely utilized as "green cement," which can widely replace cement production.

The annual amount of unused slag from the metal industry alone would cover approximately 10 percent of the world's binder needs with Betolar's solution. This would correspond to a one percent reduction in global carbon dioxide emissions. Additionally, the potential of utilizing mining industry tailings is many times greater in comparison.

"As a new type of binder, Betolar's green cement is not only low-emission but also a genuine circular economy product. Many companies in the cement industry aim to reduce emissions by focusing on carbon capture. We go significantly further in sustainability, as our solution both reduces emissions and saves virgin natural resources," Kalpala states.

Wide benefits from the method

For Betolar, it’s the green cement that would bring significant competitive advantage in various concrete business solutions in the future, in addition to the compensation received from licensing the metal separation method. Replacing traditional cement with Betolar's green cement would reduce carbon dioxide emissions and save virgin natural resources.

The method offers significant added value to the mining and metal industries as well as other industry players by improving metal yields, reducing waste, and minimizing environmental risks. Potential users of the method include steel mills, of which there are about a thousand worldwide, and the commercial value of valuable metals recovered from their slags is significant.

"Currently, increasing the production of critical metals requires ore exploration and the establishment of mines. It is slow, expensive, and environmentally burdensome. Betolar's solution, on the other hand, is fast, cost-effective, and improves the state of the environment," says Tuija Kalpala.

Yhteyshenkilöt

Tuija KalpalaPresident and CEO

Puh:+358 50 567 6608tuija.kalpala@betolar.comLinkit

About Betolar

Betolar is a circular economy enabler and materials technology specialist, providing innovative solutions to help use industrial sidestreams to produce low-carbon and cement-free products for the mining and construction sectors. Betolar's mission is to help reduce carbon emissions and the use of virgin resources in mining and construction.

Betolar's circular economic innovations significantly reduce CO2 emissions from cement use and the use of virgin raw materials by utilizing industrial sidestreams. Betolar is continuously developing its low-carbon Geoprime solution for the mining, metals and construction industries. In addition, Betolar's AI-based data platform creates value from industrial side streams and accelerates solution development. The SidePrime analytics service, based on the data platform, maps the potential for utilization of industrial sidestreams and waste.

Betolar was founded in 2016 and is domiciled in Kannonkoski, Finland. Betolar is listed on the Nasdaq First North Growth Market. For more information www.betolar.com.

Tilaa tiedotteet sähköpostiisi

Haluatko tietää asioista ensimmäisten joukossa? Kun tilaat tiedotteemme, saat ne sähköpostiisi välittömästi julkaisuhetkellä. Tilauksen voit halutessasi perua milloin tahansa.

Lue lisää julkaisijalta Betolar Oyj

Betolar vahvistaa Suomen ja EU:n omavaraisuutta kriittisissä ja strategisissa raaka-aineissa8.4.2025 08:20:00 EEST | Tiedote

Betolarin kehittämä uusi innovatiivinen menetelmä yhdistää metallin erottelun jätemateriaalista sekä vihreän sementin valmistuksen. Menetelmä mahdollistaa arvokkaiden materiaalien, kuten kriittisten- ja strategisten metallien talteenoton poikkeuksellisen korkealla saannolla metalliteollisuuden hyödyntämättömistä kuonista ja kaivosteollisuuden rikastushiekoista. Lisäksi menetelmän keskeinen etu on arvojakeista puhdistetun jäännöskuonan jatkojalostaminen saman prosessin yhteydessä vähähiiliseksi sideaineeksi, Betolarin kehittämäksi vihreäksi sementiksi. Kaikki prosessiin syötetty materiaali hyödynnetään arvokkaina tuotteina.

Betolar has been granted a patent for a climate cabinet that standardizes the storage conditions of test samples26.3.2025 16:39:24 EET | Tiedote

Betolar has been granted a patent in Finland for a climate cabinet that standardizes the storage conditions of test samples. The patented climate cabinet offers a solution for handling test samples of hardening materials such as concrete, geopolymers, or other cement-based materials in controlled conditions. The equipment enables the control of temperature and humidity of test samples, which is an essential factor in ensuring durability and performance. The device allows for a large storage capacity of samples with a small floor area and can be placed in normal dry room laboratory facilities or, for example, in movable laboratories.

Betolarille patentti testinäytteiden säilytysolosuhteita vakioivalle olosuhdekaapille26.3.2025 12:42:37 EET | Tiedote

Betolarin kehittämälle olosuhdekaapille, jonka avulla testinäytteiden säilytysolosuhteita voidaan vakioida, on myönnetty Suomessa patentti. Patentoitu olosuhdekaappi tarjoaa ratkaisun kovettuvien materiaalien, kuten betonin, geopolyymerien tai muiden sementtipohjaisten materiaalien testinäytteiden käsittelyyn kontrolloiduissa olosuhteissa. Laitteisto mahdollistaa testinäytteiden lämpötilan ja kosteuden hallinnan, mikä on olennainen tekijä kestävyyden ja suorituskyvyn varmistamisessa. Laite mahdollistaa suuren näytteiden säilytyskapasiteetin pienellä lattiapinta-alalla ja laite voidaan sijoittaa normaaliin kuivantilan laboratoriotiloihin tai esimerkiksi siirreltäviin laboratorioihin.

Betolar studied the circular economy use of ashes generated from Alva-yhtiöt energy production using the SidePrime analysis service3.2.2025 08:15:00 EET | Tiedote

Betolar conducted a commercial AI-assisted research project for Alva-yhtiöt. The project examined the ashes generated from energy production and mapped their potential for use as a cement-replacing binder material, for example in construction, infrastructure, and mining industries.

Betolar tutki Alva-yhtiöiden energiantuotannosta syntyvien tuhkien kiertotalouskäyttöä SidePrime-analyysipalvelulla3.2.2025 08:15:00 EET | Tiedote

Betolar toteutti kaupallisen tekoälyavusteisen tutkimusprojektin Alva-yhtiöille. Projektissa tutkittiin energiantuotannosta syntyviä tuhkia ja kartoitettiin niiden potentiaalia käytettäväksi esimerkiksi sementtiä korvaavana sideaineena rakentamisen, infrastruktuurin ja kaivostoiminnan käyttöön.

Uutishuoneessa voit lukea tiedotteitamme ja muuta julkaisemaamme materiaalia. Löydät sieltä niin yhteyshenkilöidemme tiedot kuin vapaasti julkaistavissa olevia kuvia ja videoita. Uutishuoneessa voit nähdä myös sosiaalisen median sisältöjä. Kaikki tiedotepalvelussa julkaistu materiaali on vapaasti median käytettävissä.

Tutustu uutishuoneeseemme